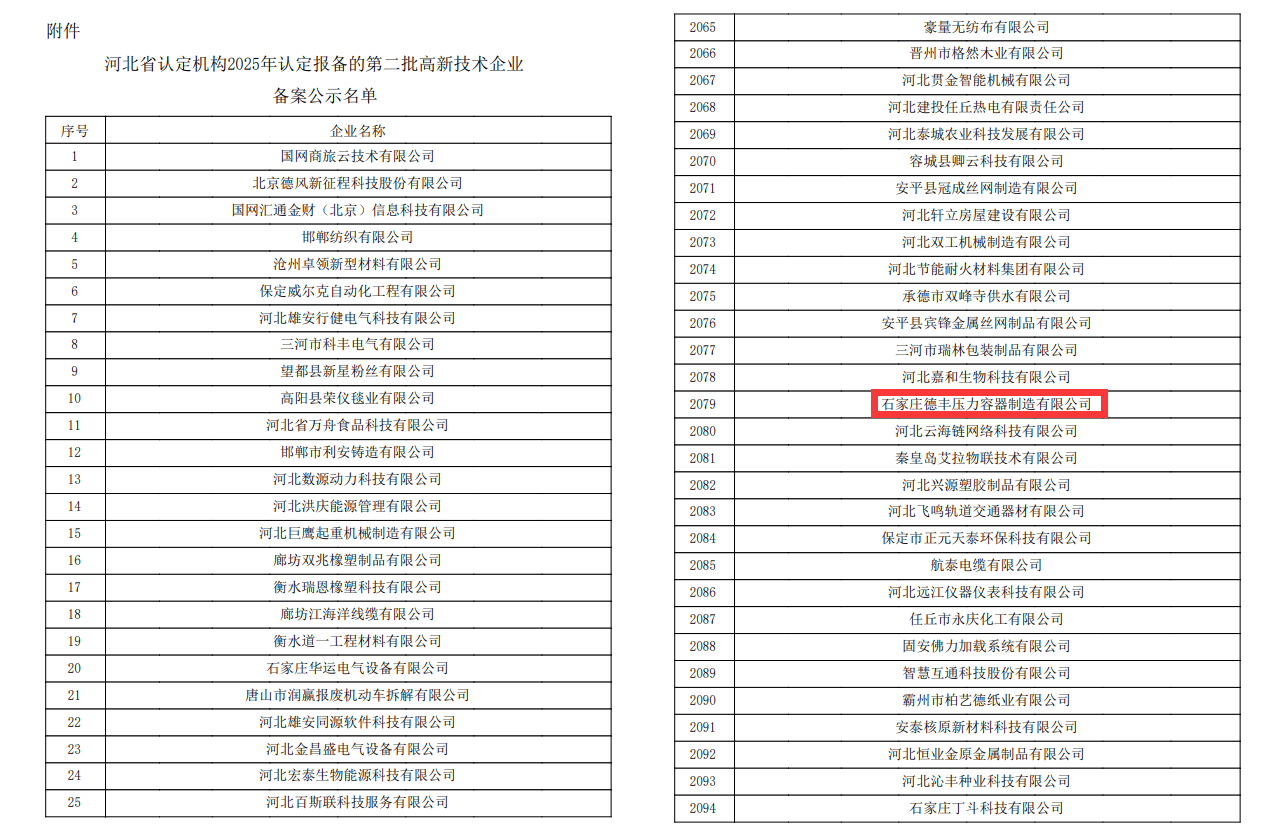

DFC Pressure Vessel Manufacturer Co., Ltd., a leading Chinese manufacturer of high-quality pressure vessels, has recently been recognized as a high-tech enterprise in the second batch of certifications issued by the Hebei Provincial Recognition Authority in 2025. This prestigious certification marks a major milestone in the company's ongoing commitment to technological innovation, research and development, and sustainable industrial growth.

High-tech enterprise recognition is one of China's most esteemed national-level accolades. It is awarded to enterprises that continuously conduct research and development, transform technological achievements into marketable products, establish independent intellectual property rights, and operate within National Key Support Areas of High Technology. For DFC, this recognition not only validates its technical capabilities but also strengthens its reputation across domestic and international markets.

A high-tech enterprise, often referred to as a National High-Tech Enterprise, represents a business that has successfully combined technological innovation with commercial viability. These enterprises are required to demonstrate sustained research and development, generate proprietary intellectual property, and carry out operations within the government-designated high-tech sectors.

Recognition as a high-tech enterprise is highly competitive, with stringent criteria in terms of technological innovation, project achievements, R&D investment, and talent development. The certification is a testament to an enterprise’s long-term commitment to advancing its technology, improving production processes, and contributing to industry innovation.

Achieving high-tech enterprise status provides multiple advantages, which can help companies like DFC accelerate growth and strengthen their market position.

Recognition as a high-tech enterprise is a rare and highly respected credential in China. Its national-level authority positions it alongside other notable certifications such as China Famous Brand Products, China Well-Known Trademarks, and National Exemption-from-Inspection Products. For technology-driven companies, this certification not only enhances brand credibility but also signals reliability and innovation to potential clients and partners.

One of the most tangible benefits is a reduction in corporate income tax. High-tech enterprises are eligible for a corporate tax rate of 15%, significantly lower than the standard 25%, which allows companies to reinvest savings into research, production, and talent acquisition.

In addition to national tax incentives, recognized high-tech enterprises can access financial rewards and grants at provincial, municipal, and district levels, further supporting innovation-driven projects.

The high-tech enterprise application process encourages companies to systematize their financial and organizational management. Enterprises that achieve this recognition are better positioned to standardize internal processes, improve operational efficiency, and attract additional funding. Moreover, these enterprises are more likely to receive research funding and preferential allocations from national, provincial, and municipal sources.

High-tech enterprise recognition also provides priority access to projects from government departments such as:

Department of Science and Technology

Department of Industry and Information Technology

Development and Reform Commission

These projects include initiatives for Innovative SMEs, Specialized and Sophisticated SMEs, Technology-Based SMEs, and platform-based research programs.

Companies recognized as high-tech enterprises enjoy tariff exemptions when purchasing imported equipment, reducing costs and enabling access to advanced machinery and technology.

High-tech enterprise status can enhance scoring in industrial park applications and government or private sector bidding processes, giving companies a competitive edge in strategic partnerships and collaborations.

Recognition improves corporate valuation and brand visibility, facilitating financing and listing opportunities. For companies like DFC, this status accelerates entry into capital markets and attracts investors seeking technologically innovative and reliable enterprises.

Founded in 1984 as Dongfang Petro-chemical Machinery Factory (DFC), the company was renamed DFC Pressure Vessel Manufacturer Co., Ltd. in 2015 to reflect its modernized structure and expanded international presence. Over nearly four decades, DFC has grown into a leading manufacturer of pressure vessels, supplying thousands of units annually for diverse industries around the world.

The company specializes in manufacturing a wide range of pressure vessels, including:

Heat exchangers and condensers

Air coolers

Ammonia synthesis towers and methanol synthesis towers

Shell-and-tube and tube-sheet heat exchangers

Rectifying, scrubber, absorption, drying, and stripping towers

Separators and surge tanks

Filters, air storage tanks, fermentation tanks, and liquid storage tanks

Liquid ammonia storage tanks, LPG and LNG tanks

Reactors, reaction stills, and reaction furnaces

Waste heat boilers

DFC serves a variety of industries, such as petroleum, natural gas, petrochemicals, fertilizers, environmental protection, water treatment, pharmaceuticals, steel, energy, paper, light industry, biological, and food sectors.

DFC maintains an annual processing capacity of approximately 15,000 metric tons of pressure vessels, reflecting its robust manufacturing capabilities. The company also has extensive experience in handling and transporting heavy industrial equipment safely and efficiently.

Largest single piece transported: 350 tons

Longest single piece transported: 59 meters

These achievements underscore DFC’s technical expertise and logistical proficiency, enabling it to support large-scale industrial projects worldwide.

DFC has built strong relationships with clients in over 30 countries, including:

Saudi Arabia, Lithuania, Canada, USA, Russia, Peru, Belgium, Costa Rica, Switzerland, Sweden, South Korea, Kazakhstan, Italy, Sudan, Turkmenistan, Niger, Chad, Iran, and Iraq.

This global footprint highlights DFC’s international reputation for quality, reliability, and compliance with rigorous technical standards.

DFC utilizes high-quality raw materials and complies with internationally recognized standards. Some of the materials include:

Carbon Steel: SA516-60, SA516-70, SA-283, SA-285

Stainless Steel: SA-240 TP304, SA-240 TP316L, SS304, SS316L

Titanium: UNS N08825

Alloy: SA-387, SB-265 Gr.1, Dual-phase Steel

Clad Plates: SA516-70+Clad TP304, SA516-70+Clad TP316L, SA516-70+Clad SB-265 Gr.1, SA516-70+Clad UNS N08825

SA-105, SA-182, SA-266 Gr.2, SA-350

SA-179, SA-106B, SA-213 TP304, SA-213 TP316L, SB-111, SB-338 Gr.2

SA193, SA-194

DFC is experienced in adhering to PED (97/23/EC), CU-TR, and CRN requirements. The company is also well-versed in global codes and standards, including:

ASME U2 Certification and ASME U Stamp Certification

ASME Code Section VIII, Division 1

AS1210

CU-TR Technical Passport

EN 13445

TEMA

API 650, API 620, API 661

PD 5500

This expertise ensures that DFC's pressure vessels meet strict safety, quality, and regulatory standards for both domestic and international markets.

DFC operates on a 200,000-square-meter site with modern manufacturing facilities and advanced equipment. Its strategic location near high-speed intersections, 250 kilometers from Beijing and 400 kilometers from Tianjin Port, allows for efficient transportation and logistics. This proximity supports timely delivery to both domestic and international clients.

The facility is equipped with state-of-the-art machinery for fabrication, assembly, and testing of pressure vessels, enabling DFC to maintain high quality and precision standards.

Being recognized as a high-tech enterprise by the Hebei Provincial Recognition Authority in 2025 marks a significant achievement for DFC Pressure Vessel Manufacturer Co., Ltd. This recognition reflects the company’s long-standing commitment to technological innovation, high-quality manufacturing, and global standards compliance.

The certification not only brings multiple benefits, including tax reduction, government incentives, tariff exemptions, and competitive advantages, but also enhances DFC’s corporate valuation and brand reputation. For nearly four decades, DFC has delivered innovative pressure vessel solutions to a wide range of industries, earning trust from clients in over 30 countries worldwide.

Looking ahead, DFC will continue leveraging its high-tech enterprise status to drive further innovation, improve production processes, expand its global footprint, and provide world-class solutions to meet the evolving needs of its customers.

This recognition underscores DFC’s position as a leader in pressure vessel manufacturing, demonstrating how innovation, quality, and strategic development combine to create a resilient and internationally competitive enterprise.