In the modern medical and industrial sectors, liquid oxygen tanks play a crucial role. These tanks are used to store liquid oxygen for essential purposes such as supplying oxygen for hospital respiratory needs. However, for first-time users of liquid oxygen tanks, there may be some confusion and safety hazards during usage. This article will explore the uses, structural characteristics, and safety precautions of liquid oxygen tanks.

Uses of Liquid Oxygen Tanks

Liquid oxygen tanks are specialized containers designed to hold liquid oxygen, widely recognized and trusted in the medical and industrial fields. Liquid oxygen is commonly utilized in places like hospitals to fulfill the demand for oxygen. The primary uses of these tanks include providing respiratory oxygen for hospitals and fulfilling oxygen requirements in industrial processes.

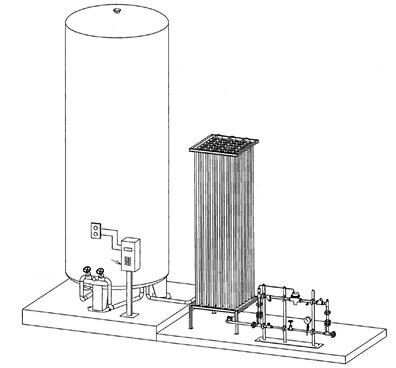

Structural Characteristics

Liquid oxygen tanks generally come in two types: vertical and horizontal. They consist of an inner container and an outer container. The inner container is typically made of 304 stainless steel, while the outer container is made of ordinary carbon steel, undergoes vacuum treatment, and is filled with insulating perlite to achieve thermal insulation.

Safety Precautions During Usage

When handling liquid oxygen tanks, it's imperative to adhere to strict safety protocols to prevent accidents and ensure the well-being of personnel and the surrounding environment. Below are key safety precautions to follow:

Operators using liquid oxygen tanks must be familiar with mechanical equipment, piping, and valve systems, understand the hazardous characteristics of liquid oxygen, and strictly control the surrounding environment. They must operate according to operational procedures and undergo training and evaluation from quality and safety supervision departments at the municipal level or higher. Operators must also hold professional qualification certificates for practical operation of high-pressure containers and take appropriate protective measures before starting work.

2. General Precautions for Users

General users should be aware of the following issues when using liquid oxygen tanks:

- The storage equipment must have grounding devices to conduct static electricity and be equipped with lightning protection devices.

- Pressure gauges should be calibrated regularly, and safety valves must be made of stainless steel.

- Wear antistatic clothing and avoid wearing shoes with metal components.

- Liquid oxygen should not splash onto unprotected skin, as it may cause frostbite and oxygen toxicity. Despite safety measures taken inside the liquid oxygen tank, special attention should still be paid to the safety of items, as liquid oxygen is highly flammable and explosive.

In conclusion, liquid oxygen tanks play an indispensable role in the medical and industrial fields. However, strict adherence to operational procedures and safety precautions is essential during usage to ensure the safety of personnel and equipment. Proper use of liquid oxygen tanks not only effectively meets the demand for oxygen but also ensures the safety of life and property. Therefore, users should pay special attention to safety issues when using liquid oxygen tanks to ensure the stable operation of equipment and the safety of personnel.

English

English Español

Español русский

русский