In industrial water treatment, multi-media filters play a pivotal role. As efficient and practical filtration equipment, they greatly contribute to ensuring water quality and conserving water resources. This article delves into the application scenarios, working principles, key selection points, and routine maintenance of industrial multi-media filters, aiding in a better understanding and utilization of this equipment.

Working Principle

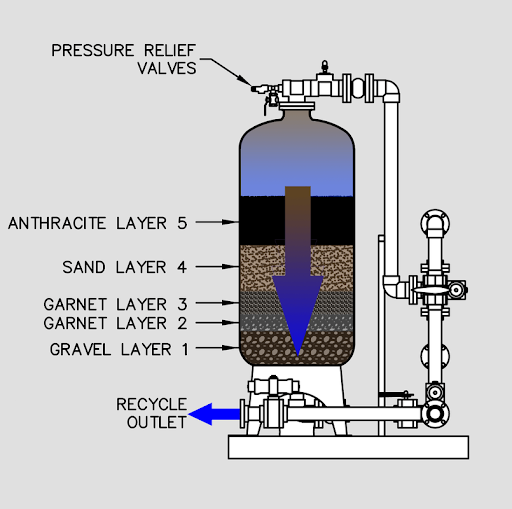

Multi-media filters primarily rely on physical action, filtering water flow through a media bed to remove impurities such as suspended solids, colloids, and turbidity. The principle involves impurities being trapped on the surface or within the interstices of the filter media as water flows through. Common filter media include quartz sand, activated carbon, anthracite coal, among others, chosen based on specific requirements.

Application Scenarios

Multi-media filters find extensive use across various industries including power generation, chemical processing, metallurgy, and electronics.

- Power Generation: Employed to remove suspended solids and colloids from boiler feed water, enhancing steam quality and prolonging boiler lifespan.

- Chemical Processing: Primarily used for reverse osmosis pre-treatment, eliminating large particulate impurities from water to protect reverse osmosis membranes and ensure stable water quality during production.

- Metallurgy: Utilized in the treatment of blast furnace cooling water to prevent pipe blockages and scaling, ensuring uninterrupted equipment operation.

- Electronics: Applied in the pre-treatment stage of ultrapure water production to meet production requirements and safeguard the quality of electronic products.

Routine Maintenance

Routine maintenance is crucial for ensuring the normal operation and longevity of multi-media filters.

- Visual Inspection: Regularly inspect the equipment for leaks, corrosion, or any visible damage, facilitating timely repairs.

- Component Fastening: Check the tightness of all components to prevent loosening and potential equipment failures.

- Media Cleaning: Periodically clean or replace the filter media to maintain filtration efficiency and ensure optimal equipment performance.

- Comprehensive Inspection and Maintenance: Conduct regular comprehensive inspections and maintenance of all equipment components including seals, valves, and control systems to uphold equipment integrity and extend service life.

Industrial multi-media filters serve as efficient water treatment equipment widely employed across various industries. Understanding their working principles, application scenarios, key selection points, and routine maintenance is crucial for optimal utilization and maintenance of these devices, providing stable and reliable water quality assurance for industrial production. Additionally, scientific and reasonable maintenance measures can maximize the effectiveness of multi-media filters, improve industrial water treatment efficiency, and promote sustainable industrial development.