In the construction industry, bulk cement storage tanks play a crucial role as essential equipment for storing cement during the construction process. This article delves into the working principles, installation procedures, and maintenance methods of cement storage tanks to ensure their proper operation and prolong their lifespan.

I. Working Principles of Cement Storage Tanks

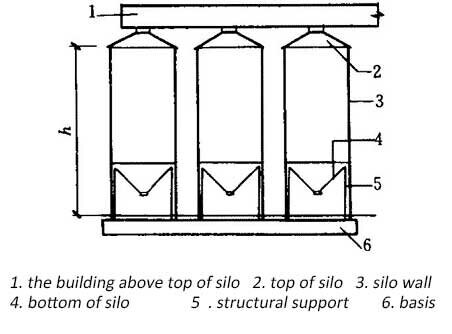

Bulk cement storage tanks are designed with a closed structure, suitable for storing various bulk materials such as grain, cement, and fly ash. Their operation is based on equipped level sensing systems, which accurately display the position and quantity of materials. Additionally, the inclusion of a venting device prevents the solidification of materials. Depending on the structure, bulk cement storage tanks can discharge materials through screw conveyors or pneumatic conveying systems, ensuring smooth material transfer.

II. Installation of Cement Storage Tanks

Proper installation is crucial to ensuring the normal operation of cement storage tanks. Taking a concrete mixing plant as an example, cement storage tanks should be installed near the control tower. During the installation process, the following points should be noted:

- Use specialized cranes to erect the cement storage tank and place it on the precast concrete foundation, ensuring the verticality and stability of the tank body.

- Strengthen wind and lightning protection measures to enhance the safety of the cement storage tank.

- Ensure that the bottom of the support legs is firmly welded to the embedded parts of the foundation.

- The foundation must comply with architectural design specifications to ensure stability.

- Avoid applying strong force or impact to the cement storage tank to prevent damage.

- Install pressure relief valves to prevent incidents of tank explosion.

III. Maintenance of Cement Storage Tanks

The use of cement storage tanks depends not only on correct operational methods but also on post-installation cleaning and maintenance. Regular maintenance not only ensures efficient performance but also extends the equipment's lifespan. The following are key aspects of cement storage tank maintenance:

- Dust Removal and Cleaning: Regularly inspect the ash cleaning system, removing cement from filter bags to prevent blockages and environmental pollution.

- Safety Measures: Regularly maintain all components of the cement storage tank to ensure its safety and reliability.

- Cleaning Techniques: Avoid using excessive force to remove concrete deposits inside the tank, only use chisels for cleaning.

- Filtration Systems: Check whether filter bags in dust collectors need replacement to ensure the equipment operates properly.

- Power Systems: Regularly inspect the operation of induced draft fans to ensure the power system operates smoothly.

- Sealing Inspection: Regularly check the sealing of equipment to prevent air leaks.

In conclusion, bulk cement storage tanks are indispensable equipment in the construction industry. Understanding their working principles, installation procedures, and maintenance methods is essential for improving work efficiency, ensuring construction safety, and prolonging equipment lifespan.